Article

The Value of Quiet Pipe Performance

While safety, reliability, and cost-effectiveness are all key components of a high-performance plumbing design, there are additional elements that merit equal consideration when planning commercial projects.

Designers of commercial buildings should be particularly aware of factors that affect the acoustical performance of the facility and cautious of the potentially negative effects of value engineering during the process.

“Excessive noise from plumbing systems is typically unnoticed until the building is occupied, creating ongoing problems for the occupants,” said Tom Sharp, a field technical service representative at Charlotte Pipe & Foundry. “Unfortunately, sound attenuation is often value-engineered out of jobs due to product substitutions and misguided cost cutting.”

While most design professionals cringe when they hear the words “value engineering,” it has become a common part of how projects unfold. Developers and owners salivate when contractors propose substituting products or methods to save money, while the professional engineers who stamp the design documents worry about the unanticipated consequences.

But what are the potential consequences of substituting one product for another? And will the owner ultimately get what they wanted if the completed building strays too much from the original design?

Let’s break it down.

If there is going to be value engineering, it should be approached with the proper methodologies.

It is easier to protect the integrity of the design and realize monetary savings if the value engineering methods are implemented early in the process. This allows design professionals to identify potential pitfalls.

On the other hand, unintended consequences — such as unacceptably loud drain lines — often result from late-term value engineering. Changes made late in the construction process may allow little or no input from the original designers. Furthermore, last-minute adjustments may benefit the owner very little, if at all.

Late-stage value engineering in a commercial building project can create additional issues, including:

Excessive material usage

Labor charge overruns

Broken timelines

Makeshift solutions

Here’s an example of how value engineering can have significant consequences.

When planning a dormitory project at a small liberal arts university in the Midwest, the engineer specified cast iron soil pipe for the drain lines. The plumbing contractor, however, suggested the cost-saving measure of substituting plastic drain lines to the general contractor and the owner — a change that these parties accepted.

Soon after the university took possession of the completed facility, students began complaining of excessive noise when their dorm neighbors flushed toilets or took showers.

The quick fix involved an unproven retrofit of insulation around the pipe. The design team struggled with how to keep the sound from resonating through the studs in the wall without removing the piping and drilling larger holes. The owner even considered removing the drain lines and replacing them with quieter cast iron soil pipelines.

After a great deal of extra time, energy, and money, the contractor ended up cutting holes in several walls and stuffing sound baffling around as much of the PVC pipe as they could reach. This solution to a problem that should have never happened was far from ideal.

Measuring Sound in Cast Iron and PVC DWV Plumbing Systems

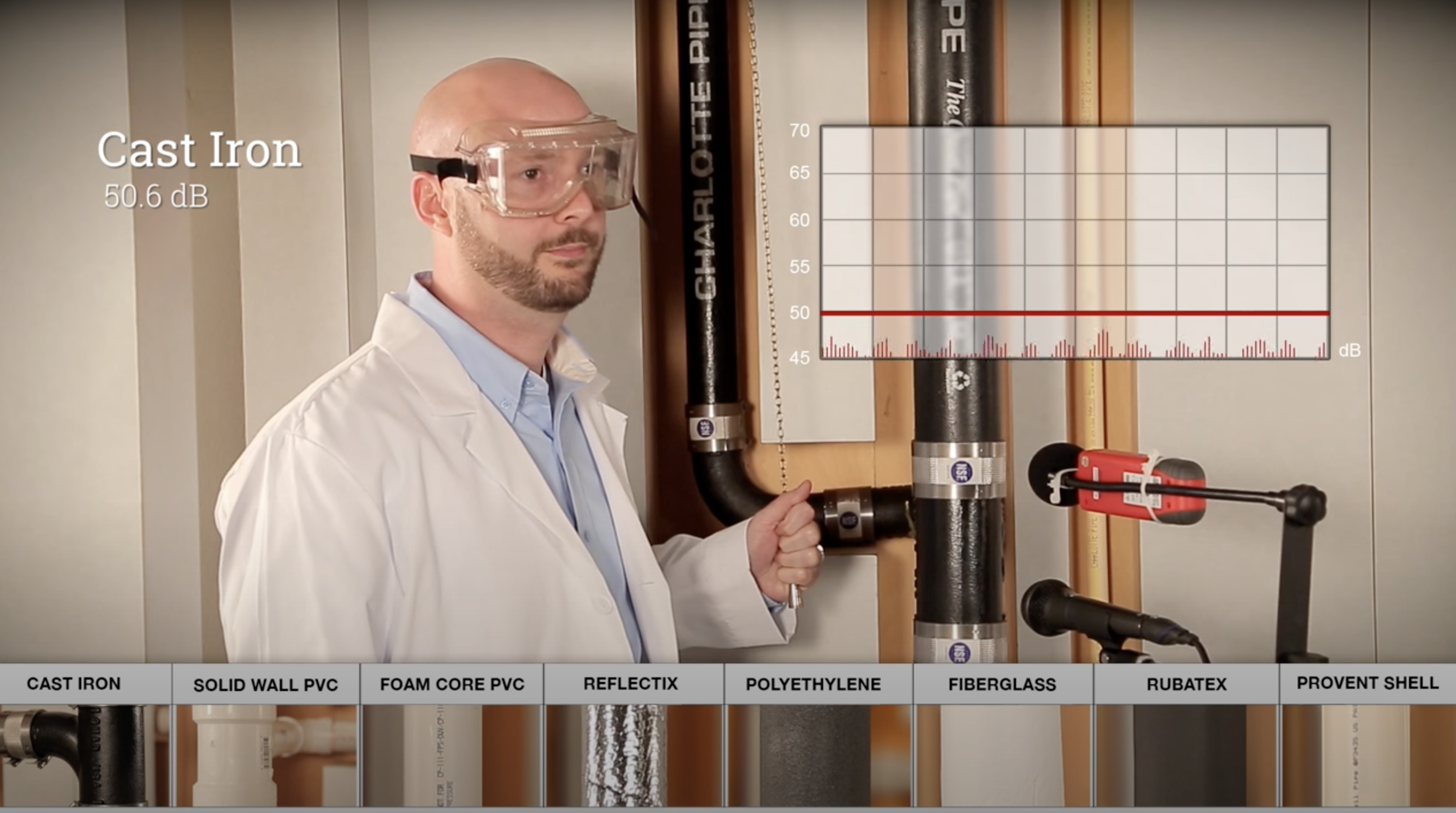

Why did the substituted plastic drain lines cause problems? For a better understanding of the difference in sound levels for a drainage system that uses cast iron versus PVC — and PVC with sound-deadening insulation — check out this video.

Understanding the Impact of Sound Attenuation

Sound attenuation concerns are not limited to dormitory living: Hotels, hospitals, schools, prisons, and other commercial buildings should also pay special attention. In all cases, excessive noise is detrimental to the indoor environmental quality for the building’s occupants.

“Noise pollution can lead to stress, hypertension, indigestion, sleep disturbances, memory problems, and more for the people who live, work, and use these commercial buildings,” Sharp said.

Hotel occupants often identify the sound of a toilet flushing as a top annoyance when spending the night away from home.

Patients in health care facilities often report that the noise level in their room at night is the quality-of-care factor with the most room for improvement.

Children in schools learn better and perform at higher levels when background noise is kept below 50 decibels.

Correctional facilities have discovered that noise levels have a direct correlation to the stress levels and activities of the inmates and the staff.

Noisy piping can cause major problems for residents in multifamily communities.

While plumbing noise has been a major distraction in nearly all types of housing for years, condo and apartment residents suffer the most. Single-family home dwellers can typically run showers, laundry, and dishwashers on their own schedule to avoid interfering with meals and sleep time. Multiunit residents, however, do not have the same luxury. They must live with the water use practices of their neighbors. This problem is often compounded by water lines installed within shared walls or in very tight spaces right up against the drywall or studs.

What causes sound in a plumbing system?

Plumbing noises are the result of cavitation, impact, drainage, and hammer, while drainage noise is caused by the rush of water and air through traps and drain pipes.

Many commercial buildings with plastic piping also experience what is often described as the “ticking noise.” This unwanted sound occurs when a plastic pipe expands and contracts as a result of temperature changes.

Designers and contractors must consider movement when designing and installing plastic piping by using either expansion/contraction joints or loops. This can be difficult to engineer properly because of the relative size of the pipe, the necessity of maintaining proper pitch, and the tight spaces in which the pipe is installed.

Proper design and installation of expansion loops is complex due to these variables:

The coefficient of linear expansion (which varies for each plastic material)

The minimum and maximum temperature the pipe will be subjected to

The length of the run

The modulus of elasticity at maximum temperature (which varies for each plastic material)

The working stress at maximum temperature (which varies for each plastic material)

The outside diameter of pipe

In contrast, cast iron will expand and contract at roughly the same rate as concrete pipe — in other words, virtually not at all.

So, how does a designer mitigate sound from their drain lines? Using a sound-deadening pipe, such as cast iron soil pipe, is the easiest answer.

Cast iron is a natural sound-deadening material with a dense molecular structure and a heavy mass. According to a study by Polysonics, cast iron is 750% more effective in silencing plumbing noise when compared to PVC. With cast iron soil pipe, sound is effectively muffled rather than transmitted, as it is with plastic pipe.

“While the impact of drain, waste, and vent sounds is often overlooked during the design process, designers can solve this problem by specifying products and systems that naturally deaden sound,”said Sharp. “The acoustical performance of the plumbing system should not be bulldozed by the value engineering process. It’s important to thoroughly consider acoustics before giving in to the promise of cost savings.”

Plumbing designers should be cautious of significant deviations from their original design intentions. Otherwise, experience may provide an expensive education on the unintended consequences of hasty decisions.