Article

Solvent Welding: How to Join Plastic Pipe and Fittings Like a Pro

Joining plastic pipe and fittings using solvent cements helps ensure tight, leak-free plastics systems. Commonly referred to as solvent welding, this simple, consistent, and reliable method of creating joints requires no special tools or costly fusion equipment.

What is solvent cement?

Neither a glue nor an adhesive, solvent cement is specially designed to temporarily soften the pipe and fitting surfaces so that they become semifluid — creating a cross-molecular bond that’s as strong as the pipe itself. Once solvent cement is properly applied and cured, solvent-welded joints are permanent, and the strength and longevity of the joints are not dependent on an adhesive life span. The only way to restart the process is by cutting and joining a new set of pipe and fittings.

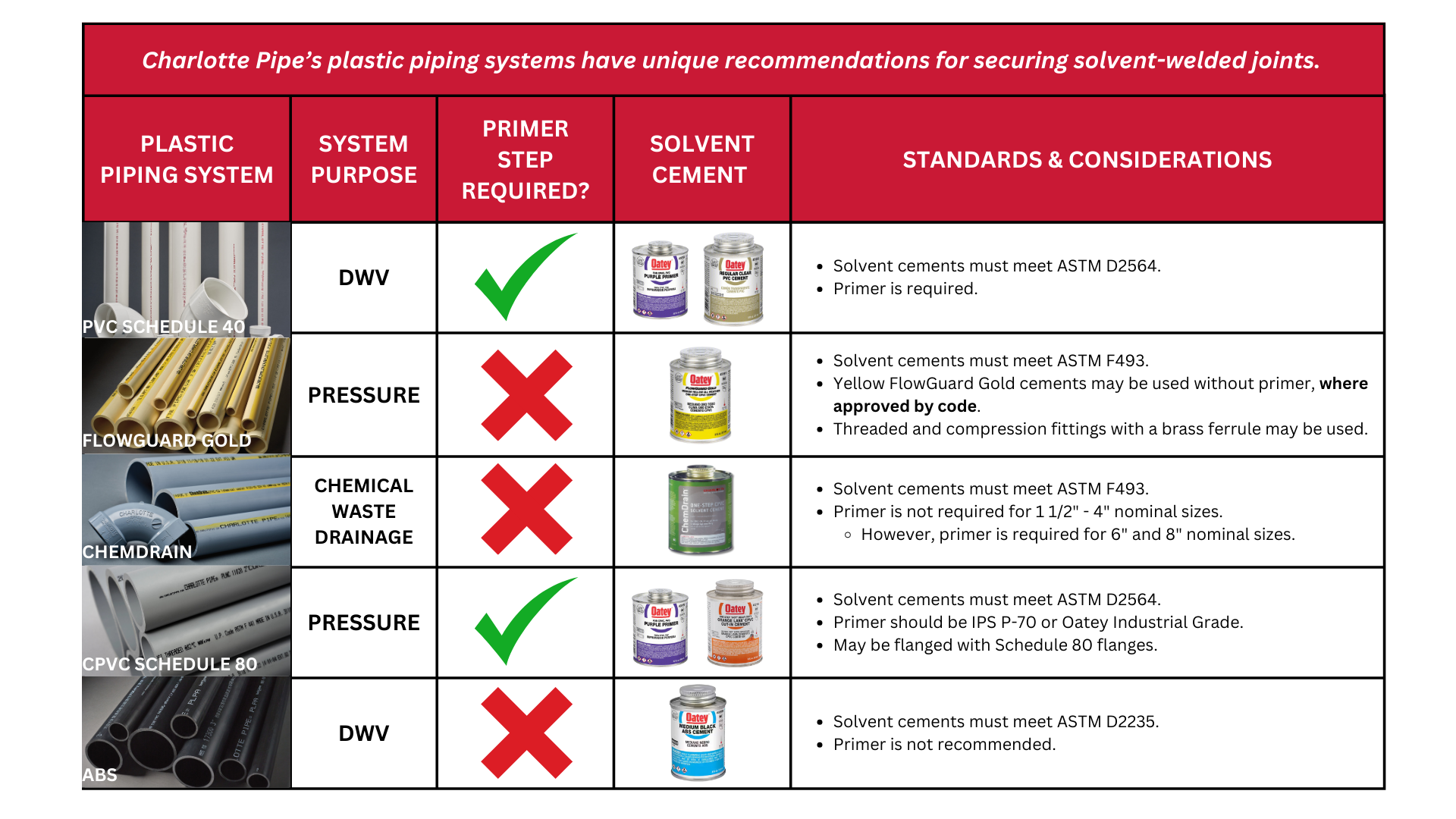

To get the most from Charlotte Pipe’s plastic pipe and fittings, compare the recommendations and ASTM requirements for joining between systems.

Once solvent cement is properly applied and cured, solvent-welded joints are permanent, and the strength and longevity of the joints are not dependent on an adhesive life span.

There are six steps required to ensure secure joints:

- Cut the pipe square.

- Review and follow ASTM adhesive standards.

- Choose the right applicator.

- Apply the solvent cement properly.

- Join the pipe and fittings securely and allow sufficient time to cure.

- Specify pipe and fittings manufactured to the nominal standard.*

Solvent Cement Options

Solvent cement is a mixture of chemicals and plastic resins used to chemically weld plastic pipe and fittings. Specially formulated cements are available for PVC and CPVC plastics systems as well as varying pipe diameters and installation conditions. Choosing the wrong cement for the application could lead to unsatisfactory results.

“Not all plastic pipe and fittings are the same. Due to the allowable dimensional tolerances, even if they meet ASTM standards, some pipe and fittings may not fit together properly,” said Brian Helms, training manager. “With this in mind, it’s important to consider specifying pipe and fittings from one manufacturer to ensure a single source of accountability.”

In addition to its robust cast iron production, Charlotte Pipe manufactures the following plastic piping systems and is committed to educating plumbing professionals on each of their unique needs.

Of note, the following standards must be considered when comparing solvent cements on the market:

- ASTM F493 for FlowGuard Gold® and ChemDrain® systems

- ASTM D2564 for Schedule 40 and Schedule 80 systems

- ASTM D2235 for Acrylonitrile Butadiene Styrene systems

Charlotte Pipe developed a one-step CPVC solvent cement designed for ChemDrain with Corzan® CPVC applications. This solvent cement helps promote system integrity by resisting hypochlorites, mineral acids, and other corrosive chemicals. Please refer to Charlotte Pipe’s ChemDrain technical manual for a full list of chemical resistance data.

The Importance of Using the Right Solvent Cement Applicator

Choosing the correct size of the applicator is as important as selecting the right solvent cement for the job.

- An oversized applicator will result in excess cement pooling inside the fitting.

- An undersized applicator prevents an adequate amount of cement or primer from being applied in the necessary time to make a proper joint.

Solvent cement and primer must be applied with an applicator as wide or as long as one half of the pipe’s diameter. For example, a pipe that is 6 inches in diameter requires an applicator that is at least 3 inches wide or long.

To primer or not to primer?

Primer is used to soften joint surfaces prior to the application of solvent cement and although clear is available, is usually tinted purple for ease of visibility. A primer’s main purpose is to clean and prep the surface of plastic pipe and fittings.

A primer step is recommended for Schedule 40 PVC and Schedule 80 piping systems. Primer is not recommended for ABS systems. Where approved by code, FlowGuard Gold pipe and fittings can be joined in one step using yellow FlowGuard Gold cements. Similarly, ChemDrain allows for one-step cement for nominal sizes up to 4”. Primer is required for 6” and 8” ChemDrain systems. Solvent cement should be applied while the primer is still wet.

High-performing joints start with identifying the right solvent cement, applicator, and primer, if recommended, for the system being installed. Once the cement is applied, allow optimal time for the joint to cure before performing a hydrostatic test. Cure times may vary. Refer to the solvent cement’s manufacturing guidelines for specific curing details.

For more information, download Charlotte Pipe’s Plastics Product Knowledge Guide.

*ASTM stipulates that the outside pipe diameter must be larger than the bottom of the fitting socket to create an interference, or consistently tight, fit.