Article

Plastic Pipe and Fittings: Top Tips to Cut and Join

When it comes to cutting and joining plastic pipe systems, precision and technique are key to ensuring a durable and reliable plumbing system. Charlotte Pipe and Foundry offers an extensive range of plastic piping systems, including FlowGuard Gold®, ChemDrain®, ABS, PVC, and CPVC. Whether for residential, commercial, or industrial applications, mastering these processes is essential for a system that performs.

In this blog post, we’ll explore best practices for cutting and joining plastic pipe, dive into the characteristics of different systems, and highlight how Charlotte Pipe’s resources can help streamline the process while meeting industry standards. These step-by-step demonstrations guide users through the intricacies of cutting and joining various plastic systems, offering practical insights to complement technical manuals, which should be followed to ensure a properly made solvent weld joint.*

For instructions on how to cut and join cast iron soil pipe, explore our blog post on the topic.

Tips for Cutting and Joining FlowGuard Gold

FlowGuard Gold is a hot and cold domestic water piping system for single-family homes that earns its reputation from its satisfactory chlorine resistance, water pressure, and flow rates. Unlike PVC, FlowGuard Gold does not require a primer step before applying solvent cement.

For the best results, follow these steps:

1. Measure and mark the required pipe length.

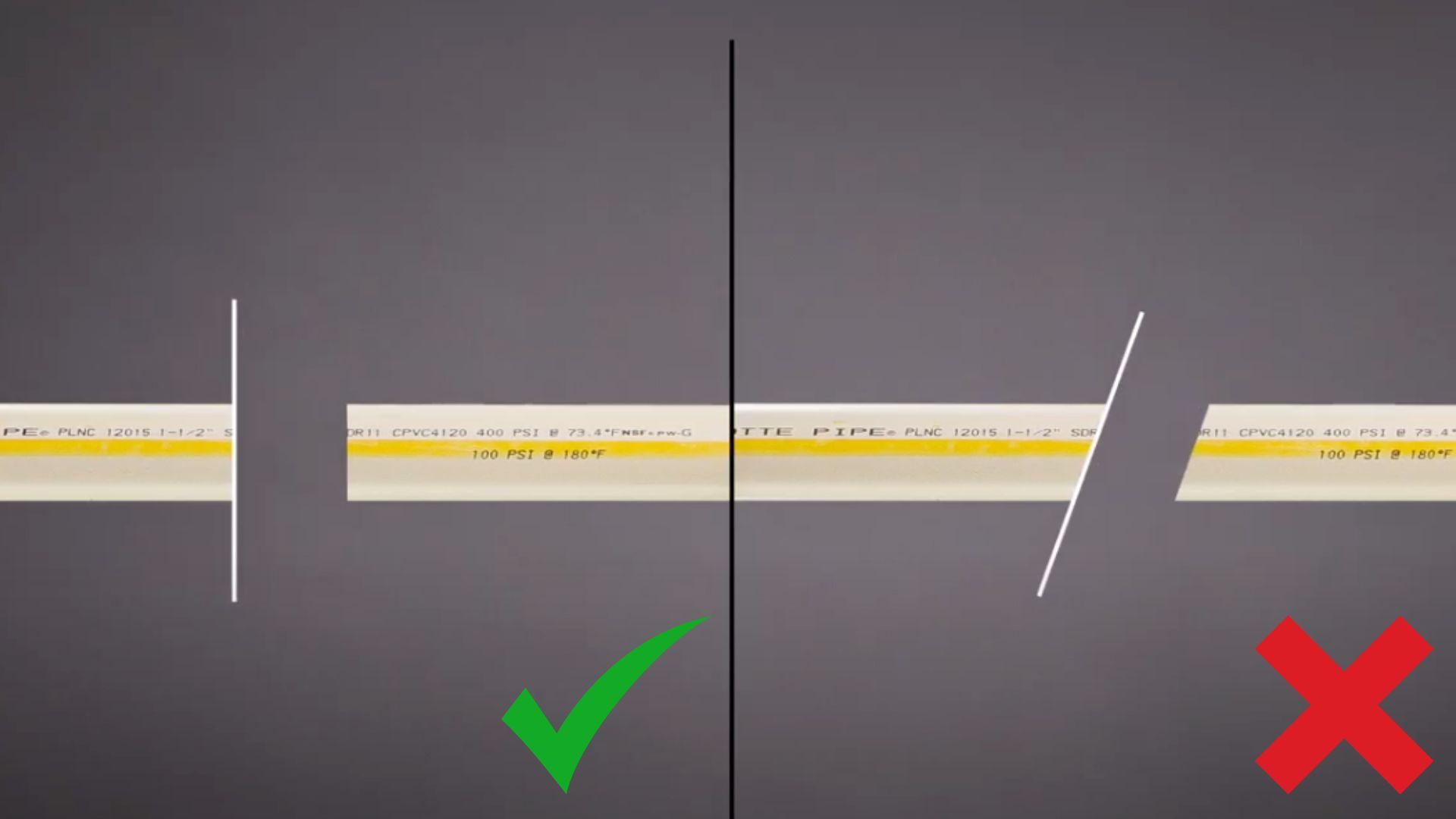

2. Cut the pipe at the required length. There are several ways to cut plastic piping, including with a handsaw, a miter saw, a cut-off saw, and a ratchet cutter. The most important thing is to achieve a square cut.

3. Remove burrs and bevel the edges to a 10- to 15-degree angle. You can use beveling tools such as a knife edge, a file, or a deburring tool.

4. Clean and dry the pipe and fittings.

5. Perform a dry fit. With light pressure, the pipe should go one-half to two-thirds of the way into the fitting hub.

Note: Pipe and fittings that are too tight or too loose shouldn’t be used.

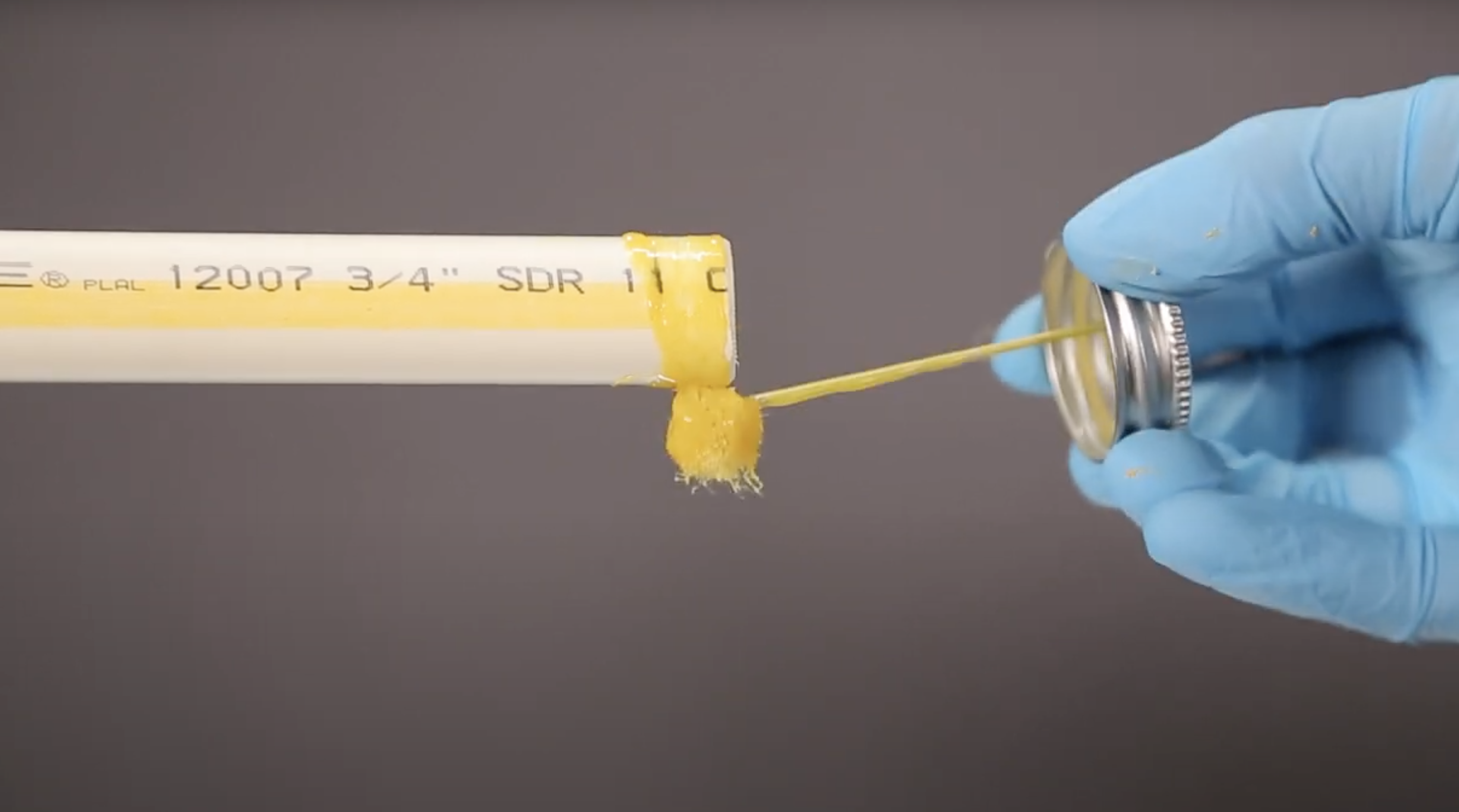

6. Apply a full, even layer of solvent cement to the pipe surface to a point a half inch beyond the hub depth. Aggressively work the cement into the surface of the pipe.

7. Apply a thin layer of cement to the fitting socket, aggressively working it into the surface.

8. Quickly assemble the pipe and fittings while the solvent cement is still fluid. (If it hardens, you have to recut the pipe and install a new fitting.) Insert the pipe into the hub using a quarter turn. Don’t try to adjust the fitting after the pipe has reached the socket bottom. Once it bottoms out, hold the pipe and fitting together until the pipe does not back out.

9. Clean up the excess cement with a rag, leaving a continuous bead of cement around the joint. Now, the joint is secure, so it will not leak and will perform for many years.

Tips for Cutting and Joining ChemDrain

ChemDrain with Corzan® CPVC is a cost-effective chemical waste system with resistance to a broad range of acids, bases, salts, and organic media in laboratories. For a complete list of ChemDrain’s chemical resistance capabilities, reference the chart in Charlotte Pipe’s ChemDrain technical manual.

With ChemDrain, it’s easy to make consistent, reliable joints using solvent cement. The process is similar to cutting and joining FlowGuard Gold. Like FlowGuard Gold, ChemDrain does not require a primer step before applying solvent cement. However, on 6-inch and 8-inch sizes, or in wet, very cold, or very hot conditions, the use of high-strength primer is recommended to ensure a well-bonded joint.

For a hassle-free, permanent weld, follow these steps:

1. Measure and mark the required pipe length.

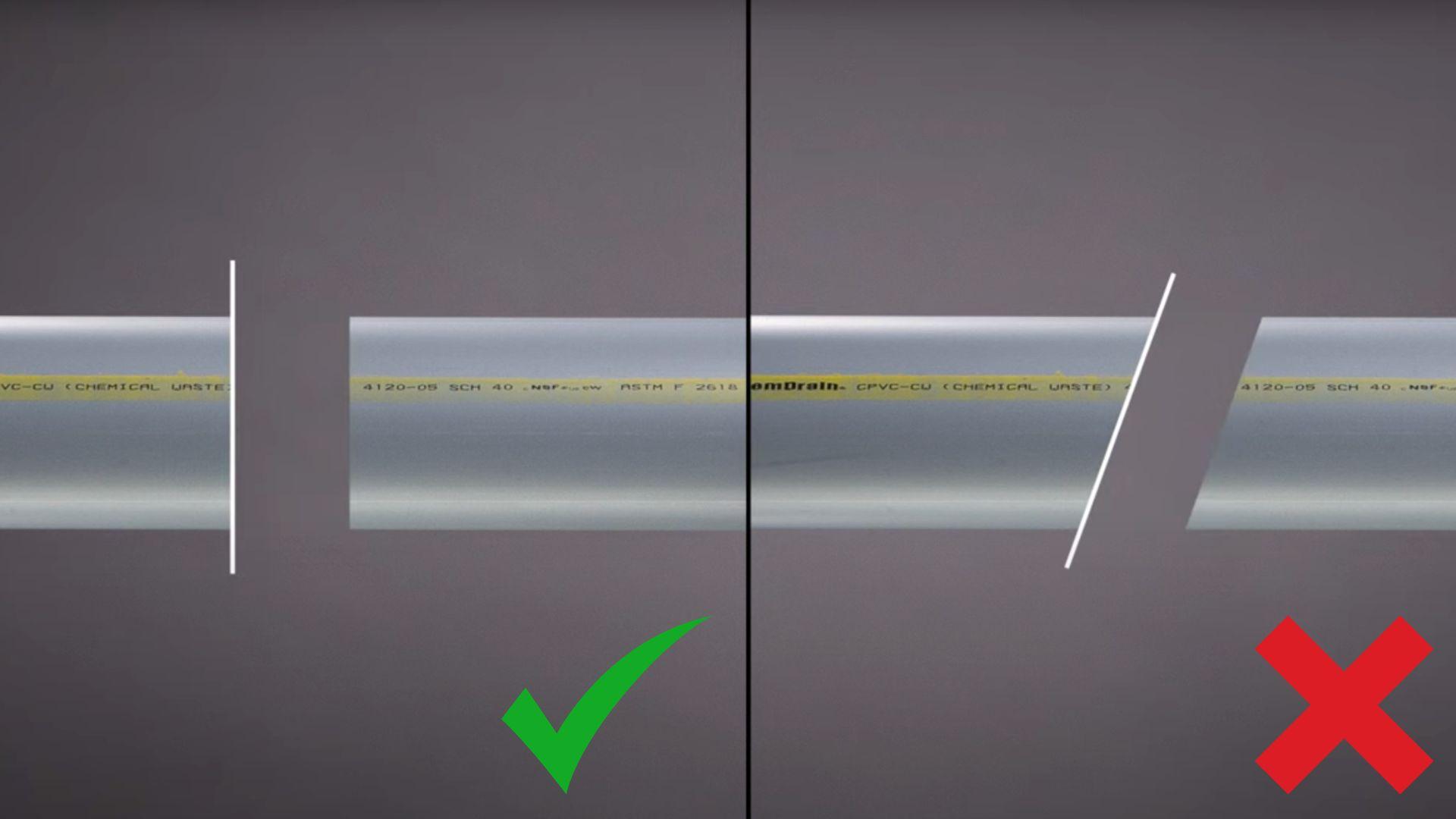

2. Cut the pipe using a handsaw, a miter saw, a cut-off saw, or a wheel type cutter.

3. Remove burrs and bevel the edges to a 10- to 15-degree angle using a knife edge, a file, or a deburring tool.

4. Clean and dry the pipe and fittings.

Repeat steps five through nine from the FlowGuard Gold guidelines previously mentioned.

Tips for Cutting and Joining PVC, CPVC, and ABS

Plastic pipe is a versatile and cost-effective plumbing material. Like FlowGuard Gold and ChemDrain, when plastic pipe is installed properly, the results are years of worry-free operation.

The stages of cutting and joining PVC and CPVC pipe and fittings mirror that of FlowGuard Gold and ChemDrain. The only addition is a primer step.

Before applying solvent cement, apply a primer to the fitting, then to the pipe, followed by a second layer to the fitting. Work it aggressively into the surface. For ABS pipe, primer is not recommended. Go straight to the cement step.

When applying solvent cement following primer, remember to:

- Apply a full, even layer of solvent cement to the pipe surface while the primer is still wet.

- Apply a medium layer of cement to the fitting socket.

- Apply a second full coat of cement to the pipe, without allowing the cement to puddle.

A Note on Joining Plastics 6 Inches or Larger

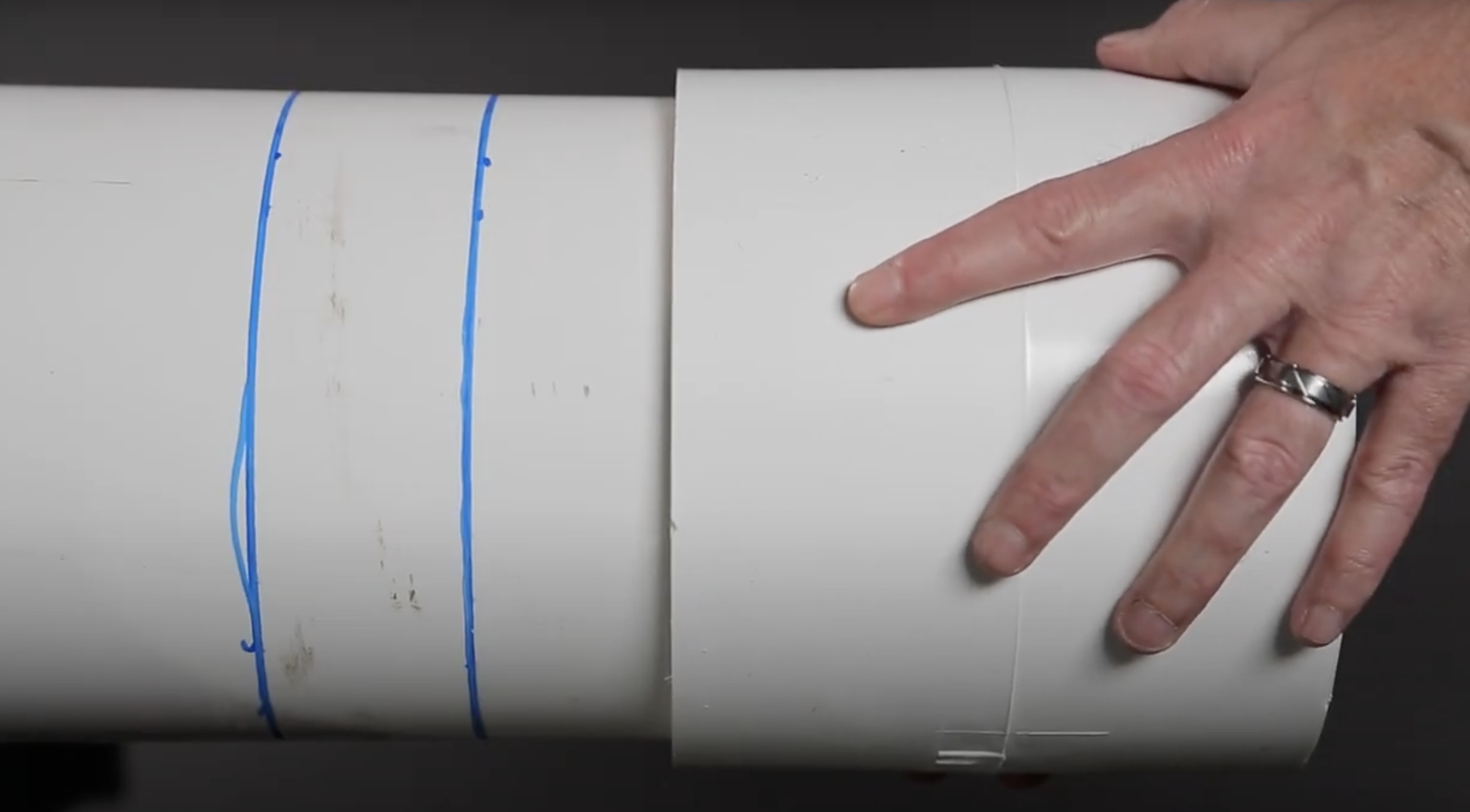

For plastic pipe that is 6 inches or larger in diameter, acceptable tools for cutting include a reciprocating saw, a mechanical cut-off with a carbide tip blade, or a handsaw.

Charlotte Pipe recommends a crew of two to three people to join pipe over 6 inches in diameter. For pipe over 10 inches in diameter, three to four people are recommended.

When installing plastic piping systems, always refer to the manufacturer’s guides for any equipment used. Browse Charlotte Pipe’s technical and installation manuals on the Technical Hub.

*This information is intended for use by licensed plumbing contractors only and is not a substitute for proper training. Reference Charlotte Pipe’s plastics technical manual for more information. Throughout the installation process, follow the tool manufacturer’s warnings and instructions, and always use protective gear.