Article

How to Cut and Join Cast Iron Soil Pipe

Cast iron pipe has been a trusted material in the plumbing industry for centuries, valued for its strength, fire resistance, and sound-dampening properties.

Charlotte Pipe, a leader in cast iron systems, provides an extensive range of resources to support professionals installing cast iron soil pipe. In this blog post, we’ll dive into the techniques and tools required for cutting and joining cast iron pipe, address common challenges, and showcase how plumbing professionals can achieve accuracy and efficiency. This serves as a high-level guide for cutting and joining cast iron soil pipe and should be followed alongside the appropriate technical manuals to ensure accuracy.* The goal is to achieve a secure fit across all joints using proper sealing techniques.

For instructions on cutting and joining various plastics systems, including FlowGuard Gold®, ChemDrain®, ABS, PVC, and CPVC, explore our blog post on the topic.

Cutting Cast Iron Soil Pipe

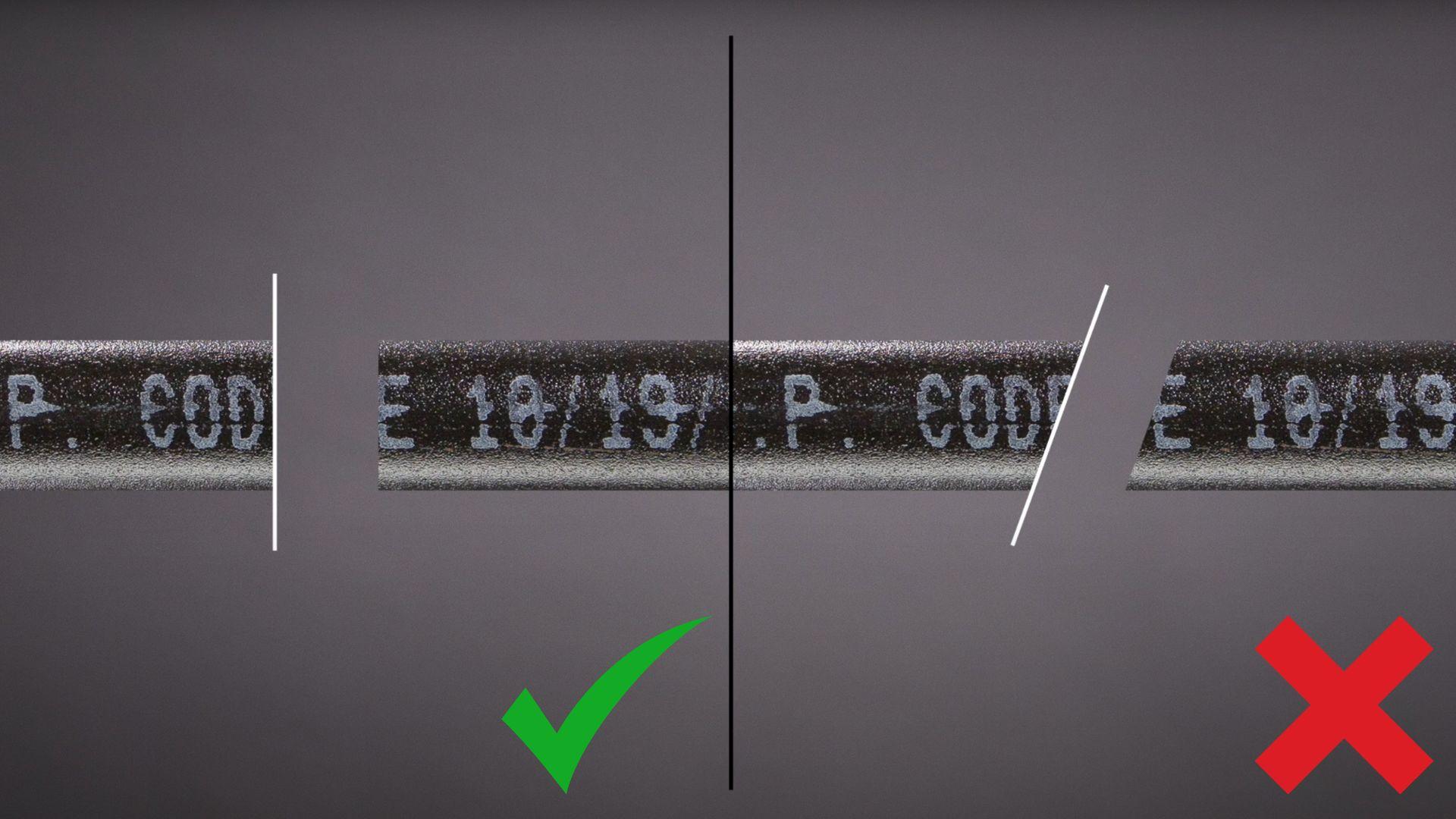

Cast iron can be cut by hand or with power tools. This guide focuses on cutting pipe with a snap cutter. The most important thing is to achieve a square cut.

Tips for Cutting Cast Iron With a Snap Cutter

1. Measure and mark the required pipe length.

2. Position the snap cutter securely so the pipe is square and the max number of cutting wheels come into contact with the pipe.

3. Score the pipe by applying enough pressure to the handle to make an indention. This step is key to making a straight, clean cut. Once scored, release the pressure and rotate the pipe a few degrees on the chain.

4. Apply quick pressure to the handle to complete the cut.

Joining Cast Iron Soil Pipe

Charlotte Pipe manufactures both hub-and-spigot and hubless cast iron soil pipe. The procedures for securing each joint are different, but the performance is ultimately the same. Following these steps will help ensure the system performs for many years without leaks.

When it comes to joining cast iron pipe and fittings, there are two common methods:

- Hubless couplings

- Compression gaskets

No matter what joint is being used, only up to 5 degrees of deflection are allowed. Any deflection beyond that will result in system failure over time. For greater bends in the pipe, a fitting should always be used.

Depending on the application, couplings are available in different sizes and strengths. As with pipe cutting, the basic procedure is the same across the board.

Joining No-Hub Cast Iron With Hubless Couplings

1. Make sure pipe ends are smooth and clean, and ensure the coupling and gasket are clean and undamaged.

2. Insert the pipe into the gasket until the pipe end hits the internally molded shoulder.

3. Insert the second pipe or fitting into the gasket as far as it will go.

4. Slide the coupling assembly over the gasket. Tighten the coupling clamps using the correct torque wrench and in the correct order. Important: Hubless couplings require 60, 80, or 120 inch-pounds torque wrenches.

No-hub couplings are not a substitute for proper joint restraint. Charlotte Pipe recommends that all no-hub pipes be joined with shielded couplings conforming to CISPI 310, ASTM C1277, or ASTM C1540.

Joining Hub-and-Spigot Cast Iron With Compression Gaskets

1. Make sure the hub and spigot are clean.

2. Remove sharp edges with a file or by tapping with a ball-peen hammer.

3. Fold the gasket and insert it into the hub. Use a double fold or a thumb fold.

4. When the gasket is inserted, tap it with a rubber mallet or flat board until it is completely seated.

5. Lubricate the gasket on the spigot end of the pipe with pipe lubricant. For 2-, 3-, and 4-inch pipe, use regular pipe lubricant. Pipe 5 inches or larger requires adhesive pipe lubricant.

Note: The use of adhesive lubricant is not a substitute for proper joint restraint. As general rules of thumb, adhesive lubricant should always be applied to the:

- Inside of the gasket

- Outside of the spigot

- Inside of the hub

6. Line the pipe up and using a lead maul, wooden block, and mallet or pulling tool, insert it into the spigot end. Other installation methods can be found in the cast iron technical manual on page 33.

7. As the spigot is forced into the gasket, the gasket expands and forms a tight seal. When you’ve got it right, you’ll feel the pipe bottom at the end of the hub.

A Note on Adhesive Lubricant

If adhesive lubricant has been used to join hub-and-spigot cast iron and allowed to set, repositioning the pipe or fitting will damage the adhesive bond, resulting in system failure. If the installation is taking place in cold conditions (below 50 degrees Fahrenheit), Charlotte Pipe recommends keeping the gaskets in warm water until needed.

When installing cast iron soil pipe, always refer to the manufacturer’s guides for any equipment used. Browse Charlotte Pipe’s technical and installation manuals on the Technical Hub.

*Cast iron installation should only be performed by a licensed plumbing contractor who is familiar with local plumbing codes and regulations. Reference Charlotte Pipe’s cast iron technical manual for more information. Throughout the installation process, read and follow the tool manufacturer’s warnings and instructions, and always use protective gear.