Article

Calculating for Thermal Expansion and Contraction

When designing and installing a plumbing system, the impact of thermal expansion and contraction remains a chief consideration for both pressure and non-pressure applications.

Physical changes to the length of the pipe can occur as the fluid and environment temperatures fluctuate above the ambient temperature, or 73.4 F. Higher temperatures can result in linear growth of the pipe, which increases the length of the run. Lower temperatures will return the pipe run to its original length. These changes are even more pronounced in longer runs and must be considered in all plumbing systems, particularly those where the application calls for elevated temperatures.

While metallic pipe, such as cast iron, will naturally expand and contract with the building, plastic pipe requires special considerations.

Substituting plastic piping for a metallic system may reduce costs for the materials. However, it also necessitates completely reengineering the system to ensure that the effects of expansion and contraction do not damage the pipe and fittings.

“The consequences of not compensating for thermal expansion and contraction can result in system failure and property damage.” Brian Helms Training Manager

“From hairline fractures to a complete break in the pipe, the consequences of not compensating for thermal expansion and contraction can result in system failure and property damage,” said Brian Helms, training manager at Charlotte Pipe. “Thermal expansion doesn’t cause the pipe to swell; it causes the pipe to grow.”

Helms related this cyclical action to breaking a plastic credit card where the plastic weakens by bending the card back and forth until it eventually snaps in half.

“The same thing can happen in a piping system, especially where long runs are joined to 90- or even 45-degree bends,” Helms said.

Below is an example of plastic pipe failure due to improperly addressing expansion and contraction.

To accommodate expansion and contraction in plastic pipe:

- Use expansion loops or offsets.

- Leave space between elbows and hangers/restraints.

- Do not butt elbows up against studs.

- Use changes in direction as deflection mechanisms.

- Cut pipe penetration holes large enough to allow for lateral movement of the pipe without abrasion.

Resource Alert: Charlotte Pipe and Foundry’s Tech Tools app includes an expansion calculator, which provides general direction in expansion loop, offset, or change of direction design for both PVC and CPVC systems.

Understanding Expansion and Contraction in Piping Systems

When calculating how much expansion and contraction a plastic pipe system — such as FlowGuard Gold® CPVC — will experience, a crucial factor is the temperature differential, or the delta T. This is normally the difference between the installed temperature and the operating temperature.

The pipe will always be shorter at the time of installation versus when it is in service and hot water has been introduced. Once in service, the hot water running through the pipe will create a thermal expansion of about 1 inch per 50 feet of straight FlowGuard Gold CPVC pipe for every 50 F increase in temperature.

“Plastics will expand and contract four to five times more than metallic systems,” Helms said. “The temperature differential, length of pipe between directional changes, and the coefficient of linear expansion each directly influence how much the system will expand and contract.”

“Plastics will expand and contract four to five times more than metallic systems.” Brian Helms Training Manager

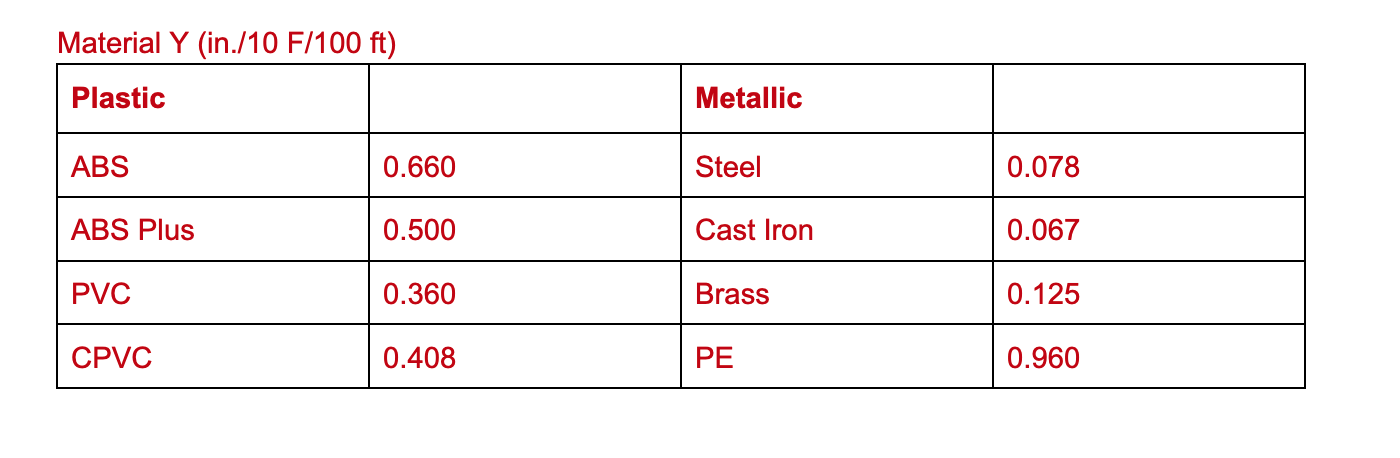

The coefficients of linear expansion (Y) for ABS, PVC, and CPVC (expressed in inches of expansion per 10 F temperature change per 100 feet of pipe) are as follows:

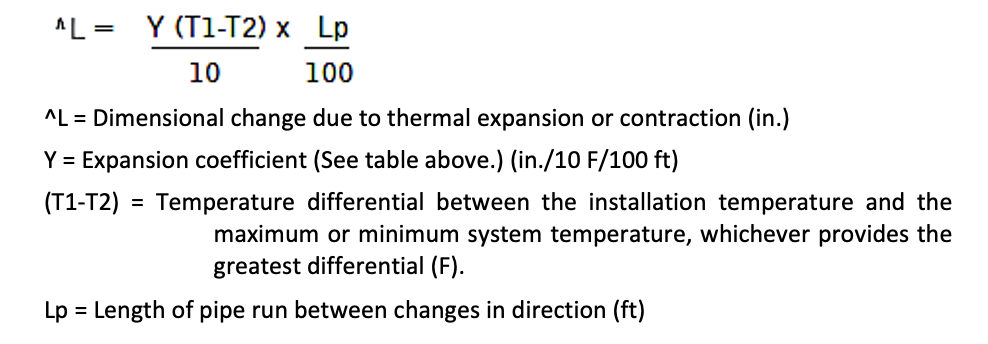

When installing CPVC FlowGuard Gold, CPVC Corzan Schedule 80, PVC Schedule 40, PVC Schedule 80, PVC PR 200, and PVC PR 160, the amount of expansion or contraction can be calculated using the following formula:

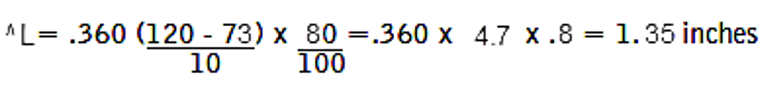

The impact of temperature fluctuation can be a major factor in hot water lines, where an 80-foot run of 2-inch-diameter PVC Schedule 80 pipe installed at 73 F can expand up to 1.35 inches when in operating service at 120 F. This is calculated by entering these variables into the formula noted above, which looks like this:

While hot water lines are most likely to be affected by expansion and contraction, both cold water lines and DWV systems can also be affected under certain circumstances.

While hot water lines are most likely to be affected by expansion and contraction, both cold water lines and DWV systems can also be affected under certain circumstances.

Using this example, an 80-foot run of plastic pipe that experiences a 47 F change in temperature will also experience concentrated compressive stress on the pipe or fitting. This force can lead to problems such as cracked fittings and distorted or cracked pipes. There is no known timetable for failure: In many cases, these problems can take years to develop because the system will withstand the excessive stress for some time before failing.

Common Methods to Compensate for Expansion and Contraction

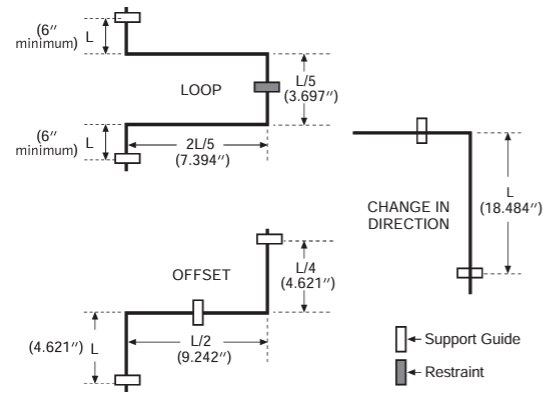

The most common methods to mitigate the effects of expansion and contraction in plastic piping systems are:

- Expansion loops

- Offsets

- Changes in direction

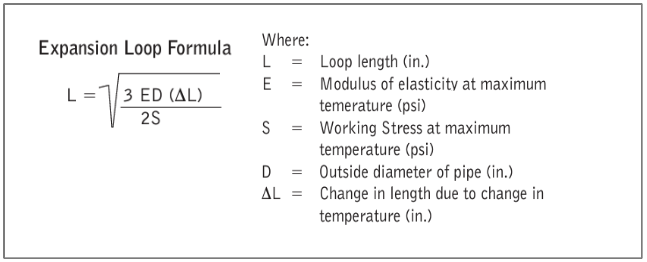

A separate formula is used to determine the dimensions of expansion loops, offsets, and changes in direction. This formula considers such factors as the modulus of elasticity and working stress of the material at a specific temperature as well as the change in length due to the temperature change. It can be expressed as:

Sizing of Expansion Loops, Offsets, or Changes of Direction

Specific dimensions of expansion loops, offsets, and changes of direction can be further calculated with the following formulas:

Guidance for Installing an Expansion Loop

- When installing an expansion loop, no rigid or restraining supports should be placed within the leg lengths of the loop.

- The loop should be installed at the midpoint between anchors as closely as possible.

- Piping support guides should restrict lateral and direct axial movement into the loop.

- The pipe and fittings should be solvent cemented together rather than joined using threaded connections.

“When using expansion joints, always follow the installation instructions and recommendations of the joint manufacturer,” Helms said. “Compensation for thermal movement is usually not required for a vent system.”

Thermal Expansion in DWV and Storm Drainage Stacks

For vertical stacks in multistory applications, compensation for expansion, contraction, or building settling is commonly achieved with offsets or expansion joints.

To accommodate thermal expansion in DWV and storm drainage stacks, secure the aboveground vertical piping at sufficiently close intervals to maintain proper alignment and support the weight of the piping and its contents. Next, ensure support at the base of the stack, and if over two stories in height, support the stack at the base and each floor with approved riser clamps.

“Both DWV and storm drainage stacks must be anchored so that movement is directed to the offsets or expansion joints,” Helms said.

Resources to Calculate Thermal Expansion

As part of Charlotte Pipe’s Tech Tools app, the expansion calculator allows plumbing professionals to calculate general changes in the length of PVC and CPVC due to temperature variations above and below the installation temperature. The calculator also provides guidance on loop, offset and change of direction sizing.

“This application is not a complete engineering reference addressing all aspects of design and installation of thermal expansion in piping systems,” Helms said. “There are many excellent references available on this topic. For example, American Society of Plumbing Engineers’ Design Handbook, Volume 4 is a great resource for engineers on designing for thermal expansion.”

Explore the Tech Tools app on your computer or download the mobile app via the Google Play store or the App Store for quick and easy access on the jobsite.