Article

Burying Plastic Pipe in Underground DWV Applications

This article is a general overview and should not be considered a complete engineering resource for all aspects of design and installation of pipe in burial applications. Charlotte Pipe recommends using the Plastics Technical and Installation Manual along with other industry references and ensuring all installations align with the requirements found in ASTM D2321.

Specifying an underground commercial plumbing system with plastic instead of cast iron soil piping requires more than just ordering different materials. Burying plastic pipe correctly can significantly impact the installation requirements, and failure to address these different dynamics risks system complications.

PVC and ABS pipe and fitting systems are flexible conduits whereas cast iron, which is inherently built to withstand earth and live loads, is considered to be a rigid conduit. Rigid conduits have a known weight in which they will fail. Conversely, the performance of plastic pipe relies on the support it gets from the surrounding soil conditions.

“It’s essential to design for a stable underground environment where plastic piping systems can succeed under a wide range of service conditions,” said Brian Helms, training manager at Charlotte Pipe and Foundry. “Although plastic piping systems may be an appealing cost saving option as compared to metal systems, they may not be suitable for every underground application and may be more labor intensive to install if done correctly. Because every project is unique and the specific project variables can vary greatly, installing plastic piping systems underground can even require the supervision of a civil engineer.”

It’s essential to design for a stable underground environment where plastic piping systems can succeed under a wide range of service conditions. Brian Helms Training Manager

3 Industry Standards for Burial

Plastic pipe and fittings should be buried in strict accordance with the ASTM standard relevant to the type of plastic piping system being installed.

- ASTM D2321: Standard Practice for Underground Installation of Thermoplastic Pipe for Sewers and Other Gravity-Flow Applications

- ASTM D2774: Standard Practice for Underground Installation of Thermoplastic Pressure Piping

- ASTM F1668: Standard Guide for Construction Procedures for Buried Plastic Pipe

In addition to these standards, plastic piping systems should adhere to local code requirements.

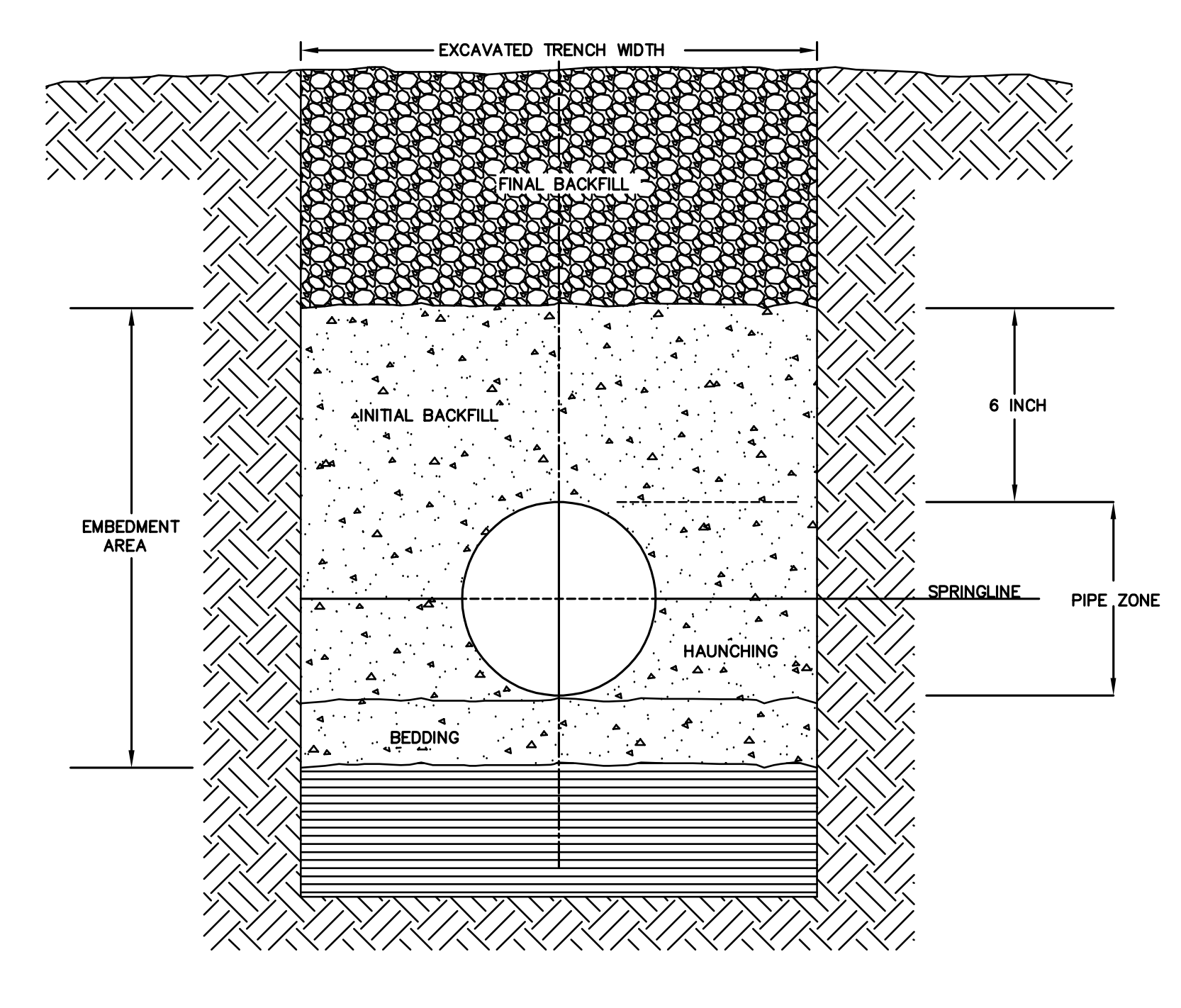

Bedding and Backfill

When installing PVC and ABS piping in underground applications, the performance of the pipe is dependent on proper side fill and compaction to withstand external live and earth loads. Start by digging a trench larger than the pipe to be installed and taking extra care to install the foundation and bedding for the system while compacting the material to the spring line of the pipe. For plastic DWV systems, Charlotte Pipe recommends that installation be performed in accordance with ASTM D2321, the Standard Practice for Underground Installation of Thermoplastic Pipe for Sewers and Other Gravity-Flow Applications.

Above is an example of proper trench bedding and backfill for pipe burial in accordance with ASTM D2321.

“These extra steps are necessary because unlike metal piping systems like cast iron, plastic piping does not have a known crush rating or weight in which it will fail. It is almost entirely dependent on proper bedding and backfill for its strength in underground applications,” Helms said. “Specific bedding and backfill requirements are set forth in ASTM D2321, which is often included in the engineer’s specification for installation. Failure to support the system with proper bedding and backfill can result in the system collapsing and failing.”

6 Recommendations for Underground Plastic DWV Pipe Burial

1. Setting Up the Minimum Trench Width

The minimum width of the trench where the pipe is being laid should be equal to the pipe’s outside diameter plus 16 inches, or the pipe’s outside diameter multiplied by 1 ¼ plus 12 inches. This provides adequate space for joining the pipe, accommodating for thermal expansion and contraction, and backfilling the pipe.

2. Adding Trench Bottom Bedding Material

A minimum of 4 inches of firm, stable, and uniform bedding material is required in the trench bottom. If rock or other unyielding material is encountered, a minimum of 6 inches of bedding should be used. Blocking should not be used to change pipe grade or to intermittently support pipe over low sections in the trench.

3. Surrounding the Pipe With Aggregate Materials

The pipe should be surrounded with an aggregate material that can be easily worked around the sides of the pipe. Backfilling should be performed in layers of 6 inches, with each layer being sufficiently compacted down 85% to 95%.

4. Compacting With a Mechanical Tamper

Charlotte Pipe recommends using a mechanical tamper on the jobsite to compact sand and gravel. These materials contain fine grains such as silt and clay. Compacting should be done by hand in the event that a tamper is unavailable.

5. Filling in the Layers

The trench should be completely filled. The backfill should be placed and spread in uniform layers to prevent any unfilled spaces or voids. Large rocks, stones, and other debris should be removed. Stone backfill should pass through a 1 ½-inch sieve. Heavy tampers or rolling equipment should only be used to consolidate the final backfill.

6. Preventing Damage to the Pipe

To prevent disturbance to the pipe and its embedment, a minimum depth of backfill above the pipe should be maintained. Pipe should always be installed below the frost level. Typically, it’s not advisable to allow vehicular traffic or heavy construction equipment to traverse the pipe trench on the jobsite.

Managing Unstable Soil Conditions

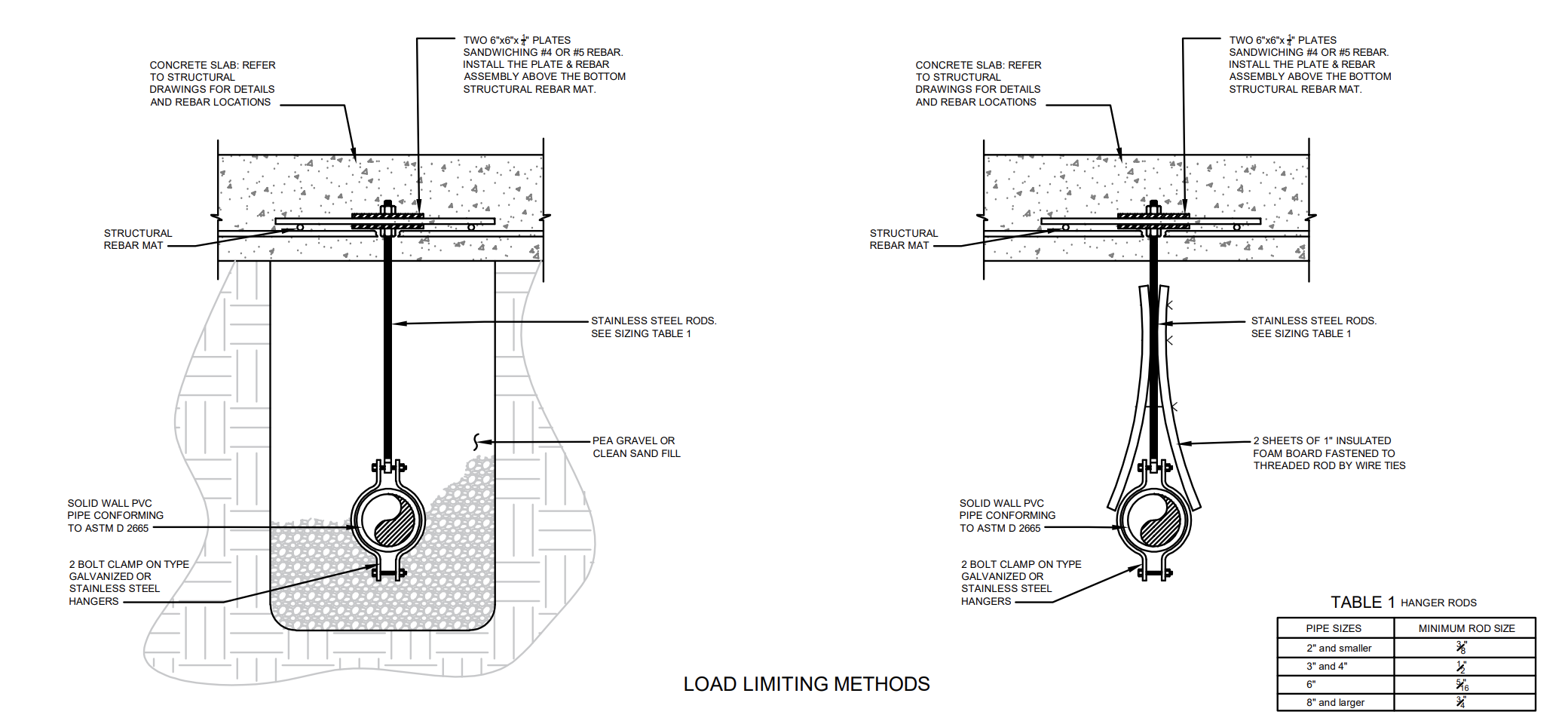

Flexible piping systems such as ABS or PVC have less structural strength than rigid metallic piping systems, which is an important consideration when designing systems buried in unstable soil. Burial of pipe beneath a building built on unstable soil can be accomplished by suspending piping systems from structural slabs. The installation of plastic pipe in such scenarios must be in accordance with ASTM F2536. Per the standard, cellular core pipe is not permitted to be used in this application due to its reduced pipe stiffness.

Above is a detail drawing for installing plastic pipe suspended from on-grade slabs. To manage environments with unstable soil, consult a soil expert or structural engineer for guidance.

What about Foam Core PVC?

Supported by the Iowa formula, stiffness varies between solid wall PVC and foam core PVC (also known as cellular core). Tests indicate that solid wall PVC demonstrates superior load capacity compared to foam core PVC.

Resource Alert: For decision criteria to help determine the appropriate system, check out a previous article on foam core PVC.

While it’s ultimately up to the plumbing engineer to determine the best material to handle the underground load, some specifiers find foam core PVC a more vulnerable material for burial and not suitable for commercial applications.

For more considerations for subsurface conditions unique to each project, refer to pages 73-74 in Charlotte Pipe’s Plastics Technical and Installation Manual.